1. GENERAL ASPECTS

Controlling the mixing water in concrete dosage is essential and important to achieve the best results in all types of constructions. It is known that every rational concrete mix starts with a value known as the “water-to-cement ratio,” which is the amount of water in liters divided by the amount of cement in kilograms used for a specific volume of concrete. The strength of that concrete, given equal materials and production conditions, depends on the water-to-cement ratio. When this ratio decreases, the strength increases. Conversely, when the ratio increases, the strength decreases. An increase in water above the specified amount in the design inevitably decreases the strength and other properties, unless an additional amount of cement is incorporated into the mix to maintain a constant water-to-cement ratio.

Fig 1: Estructuras con medición precisa de la relación agua/cemento (Foto referencial)

2. DEFINITION OF WATER-CEMENT RATIO

Concrete is a material obtained from a mixture of components: binder (cement), aggregates (sand and stone), water, and optionally, additives. The paste, composed of Portland cement and water, binds the aggregates, usually sand and crushed gravel, creating a rock-like mass. In this water-to-cement ratio, the importance of water is significant, as it and its relationship with cement are closely linked to many properties of the final material. Typically, as more water is added, the mixture becomes more fluid, increasing workability and plasticity, which offers great benefits for labor. However, it also begins to decrease strength due to the increased volume of voids created by the excess water. Thus, it can be stated that the strength of concrete is highly dependent on the weight ratio between water and cement. Likewise, curing, as mentioned in a previous article, is very important because if this process is done incorrectly, up to 30% of the expected strength could be lost. Therefore, it is recommended to cure the concrete for 28 days. It should be noted that approximately 70% of the specified strength of the concrete is achieved within the first seven days. By 14 days, the strength has reached approximately 85% of what is expected at 28 days.

3. CONSEQUENCES OF EXCESS WATER IN CONCRETE

Within the specified limits of slump and water-cement ratio, any excess water should always be avoided. In this context, excess water is considered present during pouring if there is observed water on the surface (vertical segregation) or water flowing out from the sides of the formwork (horizontal segregation). Excess water also exacerbates surface defects by increasing leakage through any holes in the formwork.

The final result can be:

- Formation of honeycombing, sand streaks, variations in color or soft spots on the surface.

- In vertical formwork, the rise of water generates weak planes between each layer of deposit. In addition to the detrimental structural effect, these planes, as they harden, contain voids through which water can pass.

- In horizontal elements, such as floor slabs or pavements, excess water tends to rise and form a weak surface layer. This layer offers little resistance to compression and abrasion, considerable shrinkage and, in general, low quality.

- Cracks in foundations and other structures.

- Deterioration of pavements in cold areas where freeze-thaw cycles occur.

- Deterioration of concrete surfaces. When the concrete has an excess of water, it exudes through the joints of the formworks, dragging the cement paste and leaving a striped and stained surface, with an unpleasant appearance.

- Porosity in structural elements, also called “bees’ nests”, can occur in mixtures with excess water, where the segregation of materials has occurred, leaving important parts of coarse aggregate without the corresponding mortar.

Fig 2: Excess water in concrete.

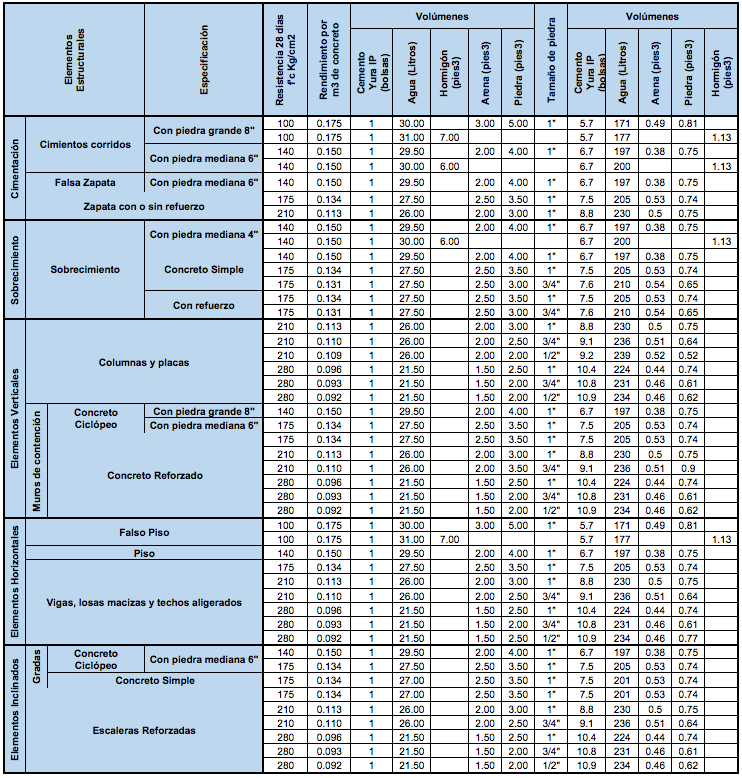

4. DOSING TIPS.

The control of the amount of water in the concrete dosage is of vital importance at the moment of making the mix design, considering that this factor will influence considerably in the development of the concrete strength, for which we present a summary table of dosages that you can use in your work with Cementos Yura IP:

Table 1: Dosage for different types of concrete and structures.

5. CONCLUSIONS

- Five very important factors must be taken into account when mixing concrete: water/cement ratio, particle size distribution, water quality and, of course, the consistency of the mix and finally the strength of the concrete.

- Excessive mixing water is a danger already recognized by builders and unfortunately, the damage it causes appears too late in life to be remedied without excessive costs.

- In order to obtain an appropriate specified concrete strength, it is always advisable to carry out the material and dosage tests in the concrete mix design.

Author: Eng. David Umiri Flores